Why BLOCK CAVING is an economically viable option for the mining industry

An insight on block caving mining method by David Sprott, Principal and Senior Mining Engineer based in Vancouver, British Columbia.

When planning to develop a new mine, or to extend the life of an open pit operation, mine planners have an alternative mining method to consider: block caving. Some deposits are either too deep to economically extract by open pit methods or are of insufficient value to justify other costlier and conventional underground methods. In the right conditions, the advantages of block caving make it an alternative that is now being considered more often.

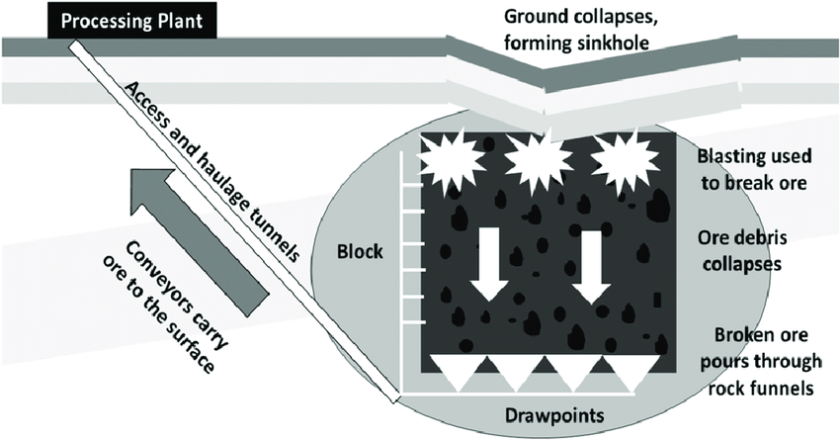

Block cave mining is an underground mass mining method that allows for the bulk extraction of large, relatively lower grade, ore deposits with substantial vertical dimension. In block caving, a large section of ore is initially undercut by drilling and blasting, creating a large unsupported roof that will start to collapse under its own weight and instability. The broken ore then breaks apart and falls into a series of pre-constructed funnels, or drawbells, and access tunnels developed underneath the caving rock mass to form ore extraction drawpoints.

As many surface mines exhaust viable reserves using conventional open pit methods, they are seeking to extend their operations by going underground to continue extracting ore. The lower operating cost of underground block cave mining can be comparable with open pit methods and can either be a viable alternative to develop a new mine or to extend the life of an existing mine. Block cave mining operating costs are typically in the order of one tenth of what other underground mining methods cost, largely driven by economies of scale where production rates can reach 30,000 to 100,000 tonnes per day. In addition, drilling and blasting costs are far less, and there are no backfilling costs.

Another key advantage to an underground mining method like block caving, as compared to open pit methods, is the large reduction in surface waste disposal needs. As open pits get deeper, their ratios of waste rock to ore often get higher and the waste must be placed in ever-increasing surface storage areas. The amount of waste rock generated from underground methods like block caving is a fraction of this, reducing surficial land impacts which is a key permitting advantage.

Factors in the Selection of Block Cave Mining

- A deposit geometry that is amenable to the method. Generally, this means a massive deposit that has sufficient height and footprint area to initiate and propagate the natural caving of the rock mass.

- Suitable deposit geomechanical characteristics such as in-situ rock fractures to encourage fragmentation during the caving process, sufficient rock mass strength to support long life drawpoints and excavation tunnels, and manageable ground stresses.

- Ore value that is not only able to cover operating costs, but also the relatively high initial capital costs, and extended pre-production periods, as compared to most other methods. As a minimum, the ore value should be two to three times the site operating costs (mining, processing, and general and administration costs).

- The acceptance of surface disturbance above the cave. This zone of disturbance must be accounted for when considering existing or planned infrastructure and environmental considerations.

Early Stage Assessment of Using Block Caving for a Deposit

The following steps should be completed when evaluating a mineral deposit for block caving:

Apply typical costs and economic cut-off values to the resource block model and assess the resulting geometry and block values in terms of block caving – size, shape and available footprint area, and potential economic margins.

Assess the available geotechnical data which could include Rock Quality Designation (RQD) data from exploration drill holes, joint/fracture density and orientation, drill core photos, and rock strength data.

Employ a suitable software tool to assess potential footprint sizes and elevations, and overall in-situ cave value.

Run multiple sensitivities on key economic inputs and determine a range of potential cave footprints, sizes and average values per tonne.

Complete a scoping-level mine design including footprint access and layout, material handling infrastructure, and mine ventilation.

Apply scoping-level cost estimates for all mine development and infrastructure, and develop a project cash flow to determine net present value (NPV) and internal rate of return (IRR).

The above evaluation process will help to direct future exploration plans and understand what the key drivers are for extracting a particular deposit using block caving. If the project passes this initial assessment, then further more detailed studies can be done at the pre-feasibility and feasibility level. These studies would include more detailed mine design, cave modelling and drawpoint scheduling, numerical stress modelling, and fragmentation assessments.

Block caving has garnered increased interest in recent years, especially as the number of new near surface deposits which can be mined by open pit methods continues to decrease. This has helped drive global interest in cost-effective underground mining methods like block caving which can be a viable alternative for consideration in mineral project evaluation.

![]()